FORGE | Re-fabricator unit for Haven-2

ROLE

LENGTH

TOOLS

SKILLS

To sustain long-duration spaceflight, in-space manufacturing must be as reliable as the food supply. Forge enables crew to recycle, reuse, and fabricate essential utility items onboard, while minimizing workload and complexity.

OVERVIEW

Individual - Personal Project

4 weeks (2025)

Solidworks, Keyshot, Procreate, Adobe Suite

Contextual research, prototyping, CAD, ergonomics

PROBLEM STATEMENT

Long-duration spaceflight requires self-sufficiency without increasing crew workload.

BACKGROUND — In-space Manufacturing

While in space, crews need the ability to adapt and create what they need on demand. In-space manufacturing enables repair, reuse, and flexibility in orbit, helping habitats become more self-sufficient and livable over time.

Existing Solutions

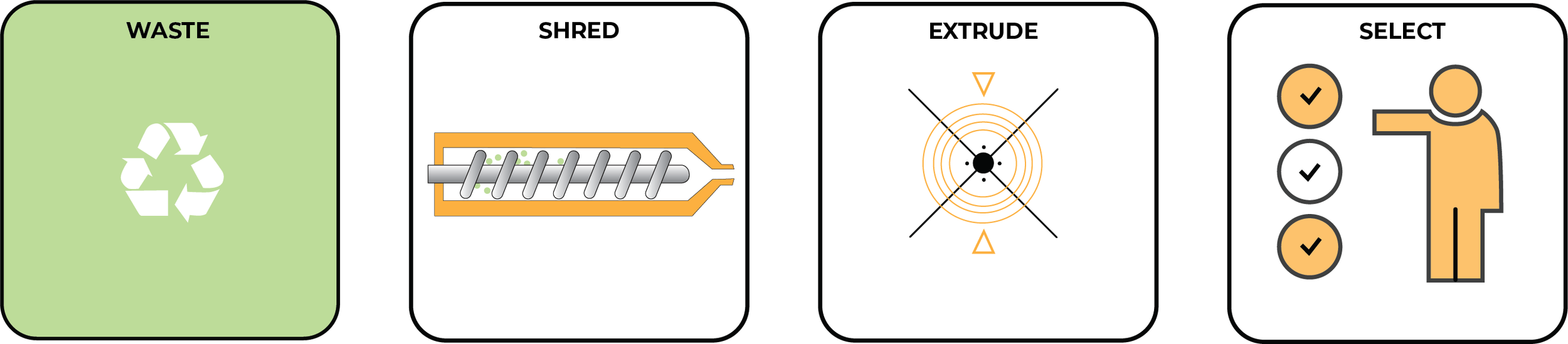

In-space manufacturing is already on board the ISS. Refabricators are designed to recycle waste material, by shredding, melting, and extruding it into 3d-printable filament.

Current System — Orbital only

Current in-space fabrication is complex, maintenance-heavy, and rigid, limiting its usefulness for long missions.

Complex interfaces

High maintenance

Industrial, Rigid design

DESIGN OPPORTUNITY

A refabrication system designed around crew comfort, simplicity, and daily use

Proposed System — Deep-space

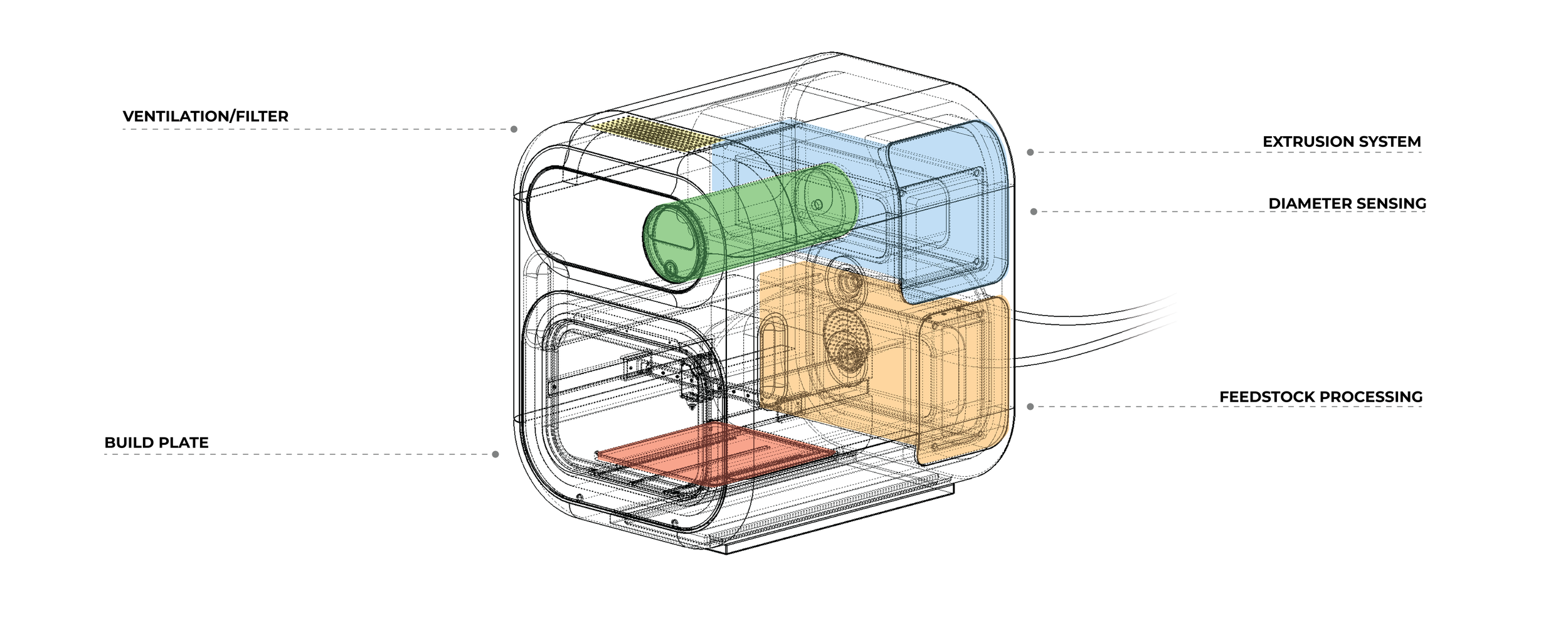

FORGE streamlines the re-fabrication process with an intuitive interface while supporting long-term sustainability.

Intuitive

Low-maintenance

Integrated

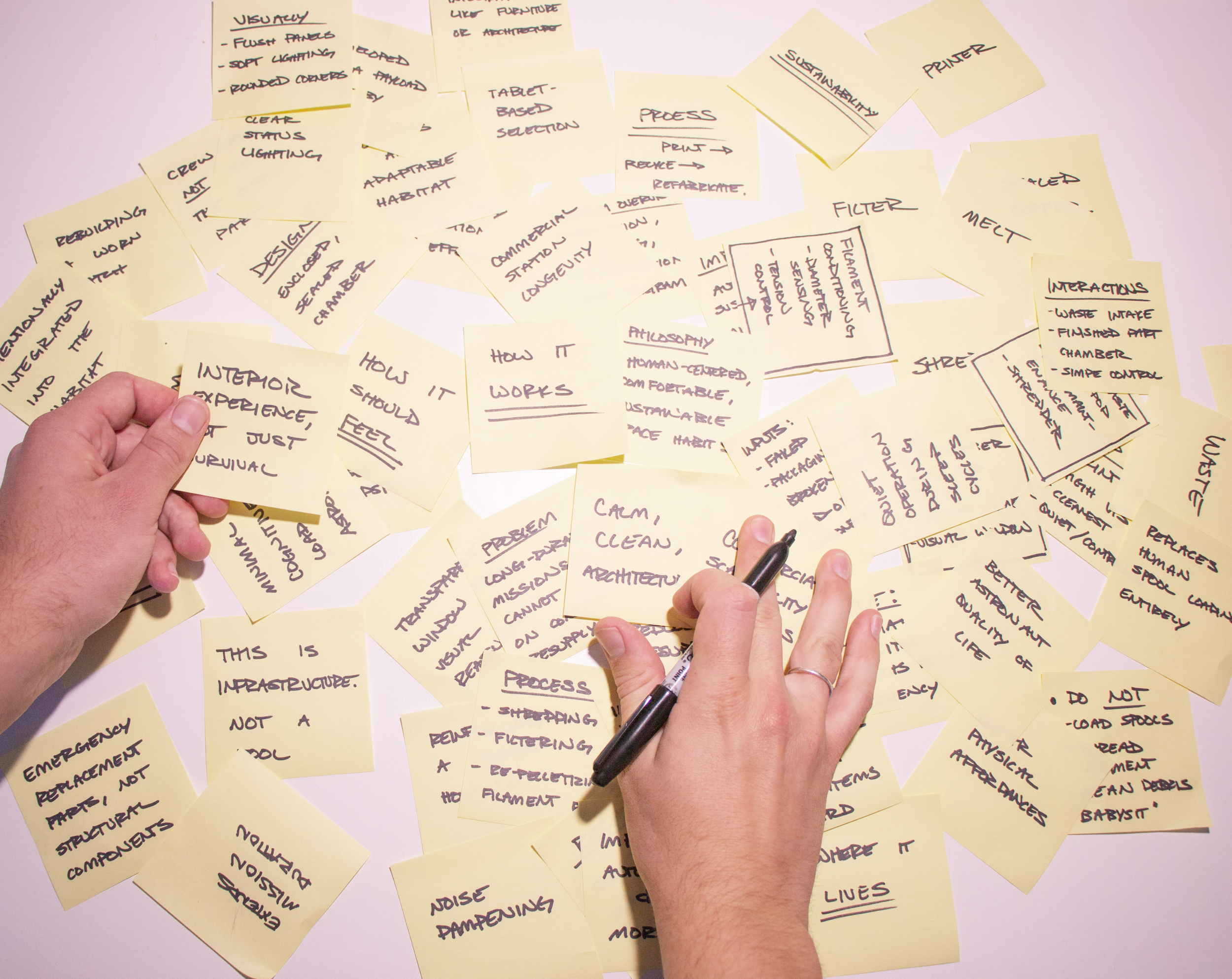

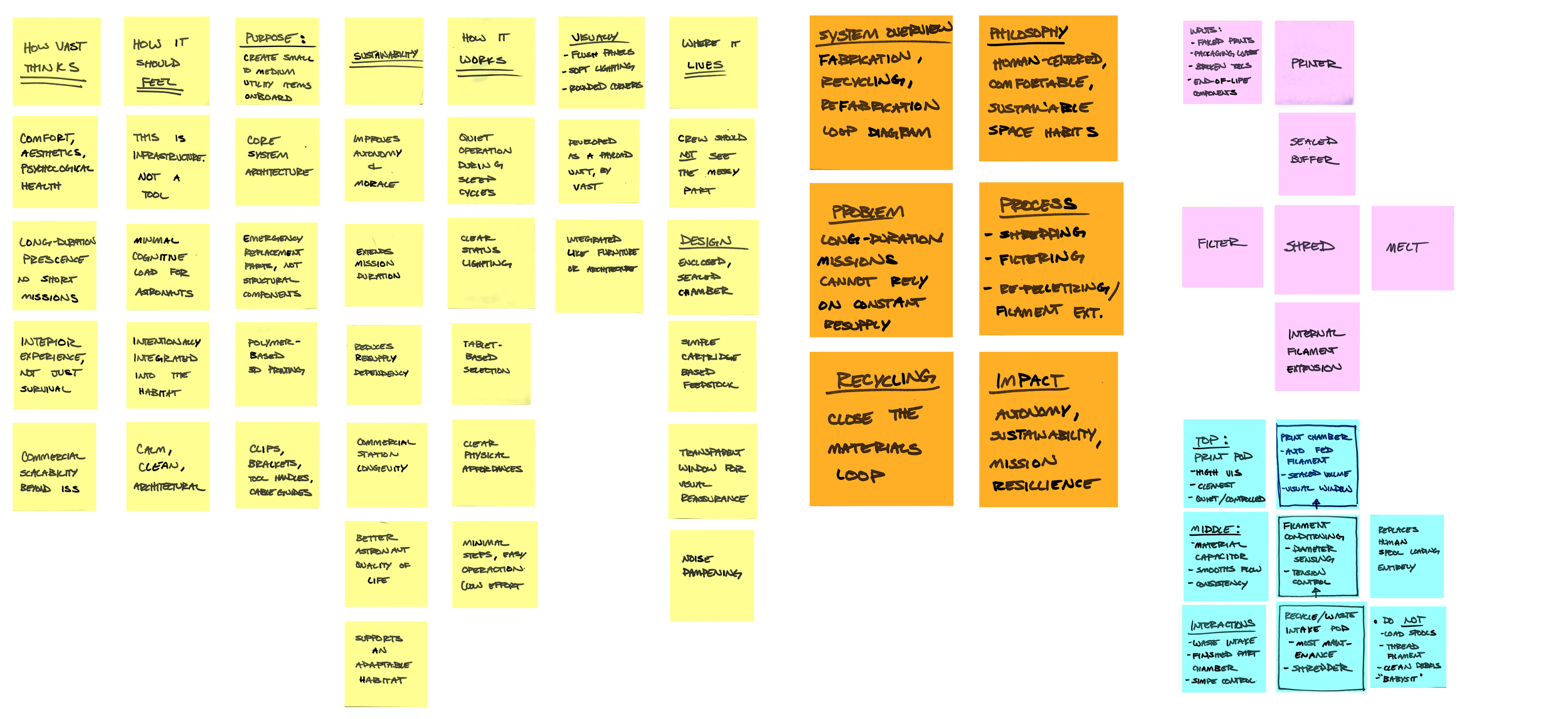

PROCESS

Research into VAST’s mission goals and technical restraints

This topic was initially foreign to me, so I was excited to dive into research on in-space manufacturing to understand the technology, goals, and requirements, and how such a system could fit aboard Haven-2.

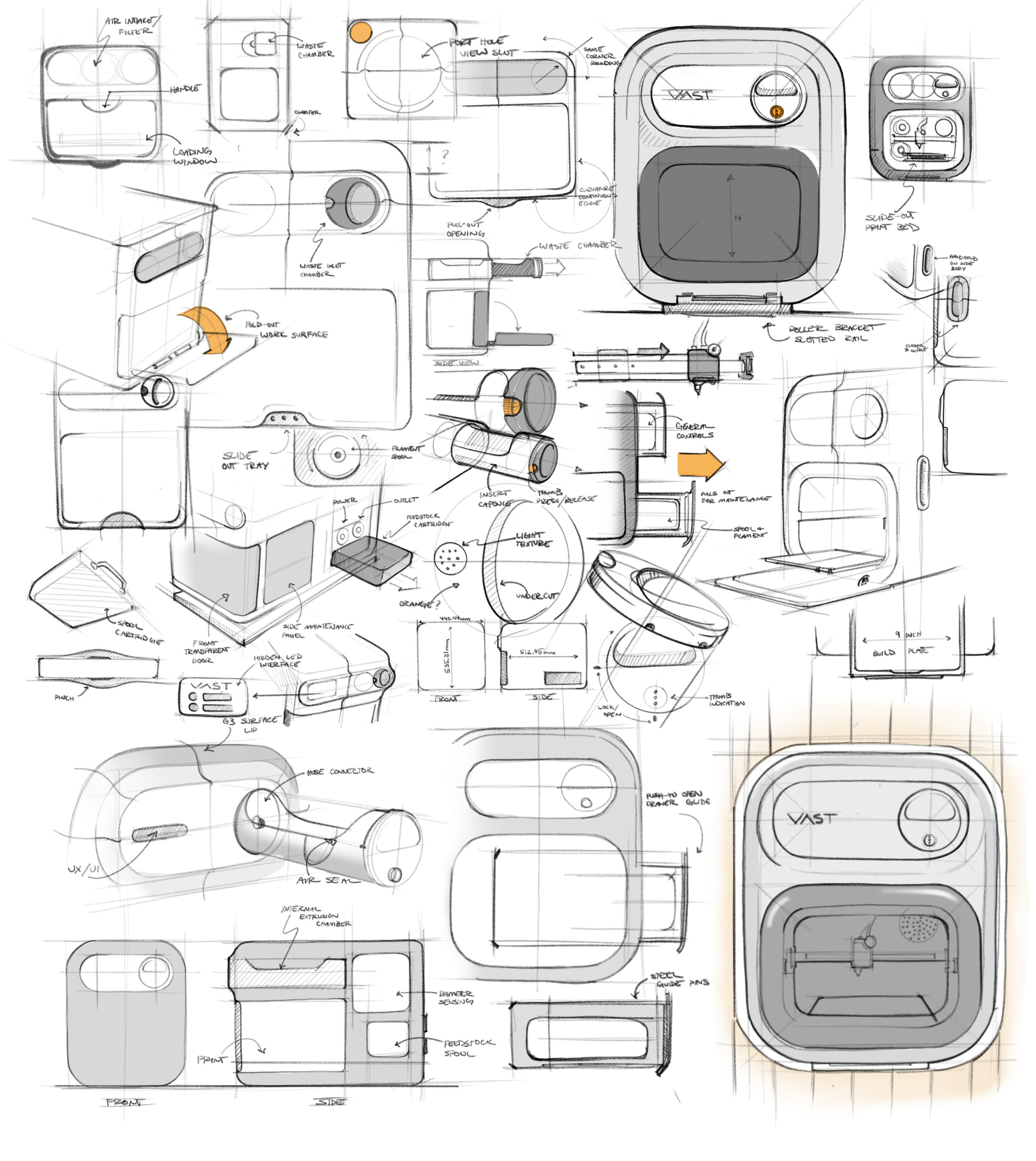

FORM LANGUAGE

Tactile surfaces | Soft geometry | Hierarchical clarity | Inviting touchpoints

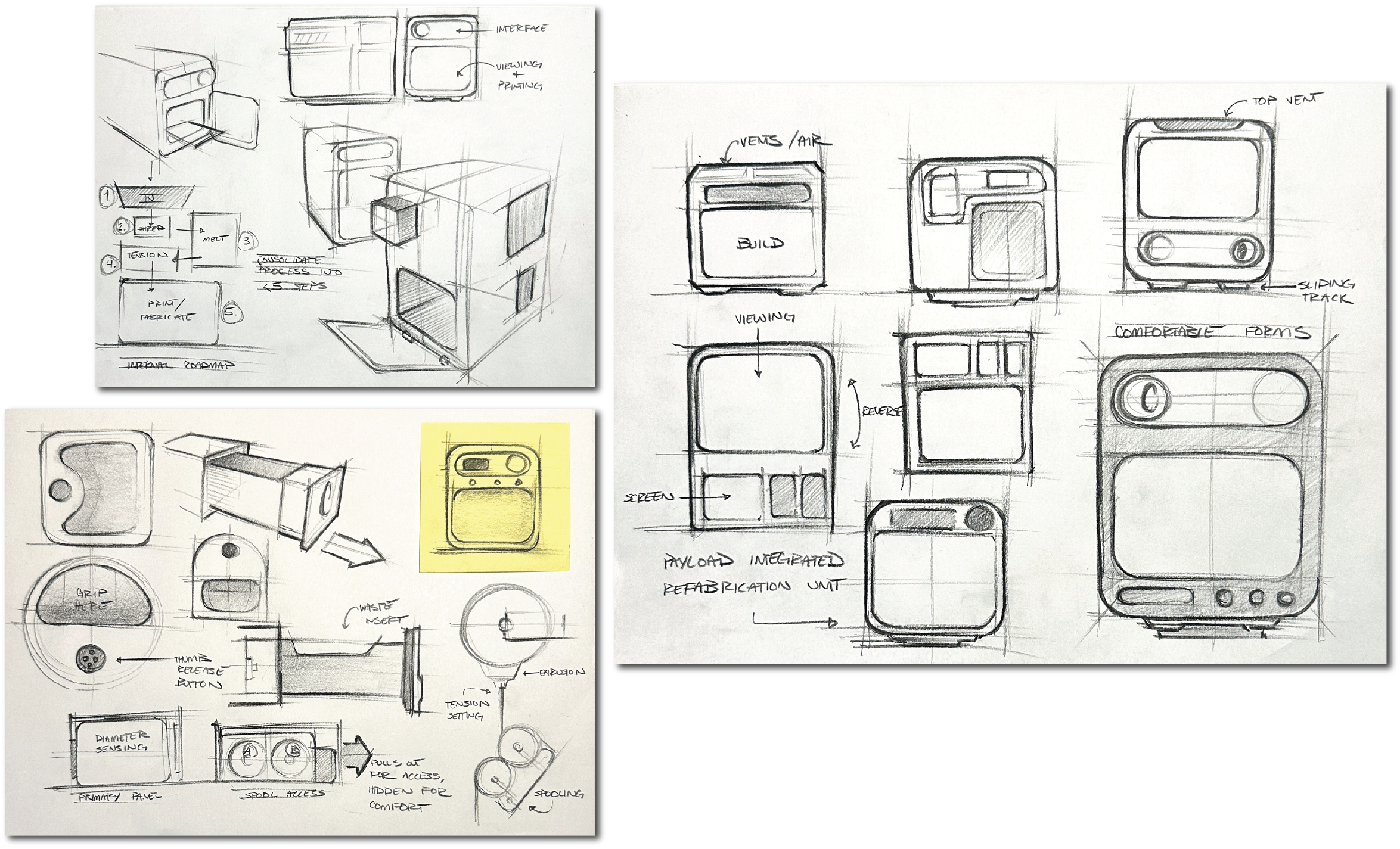

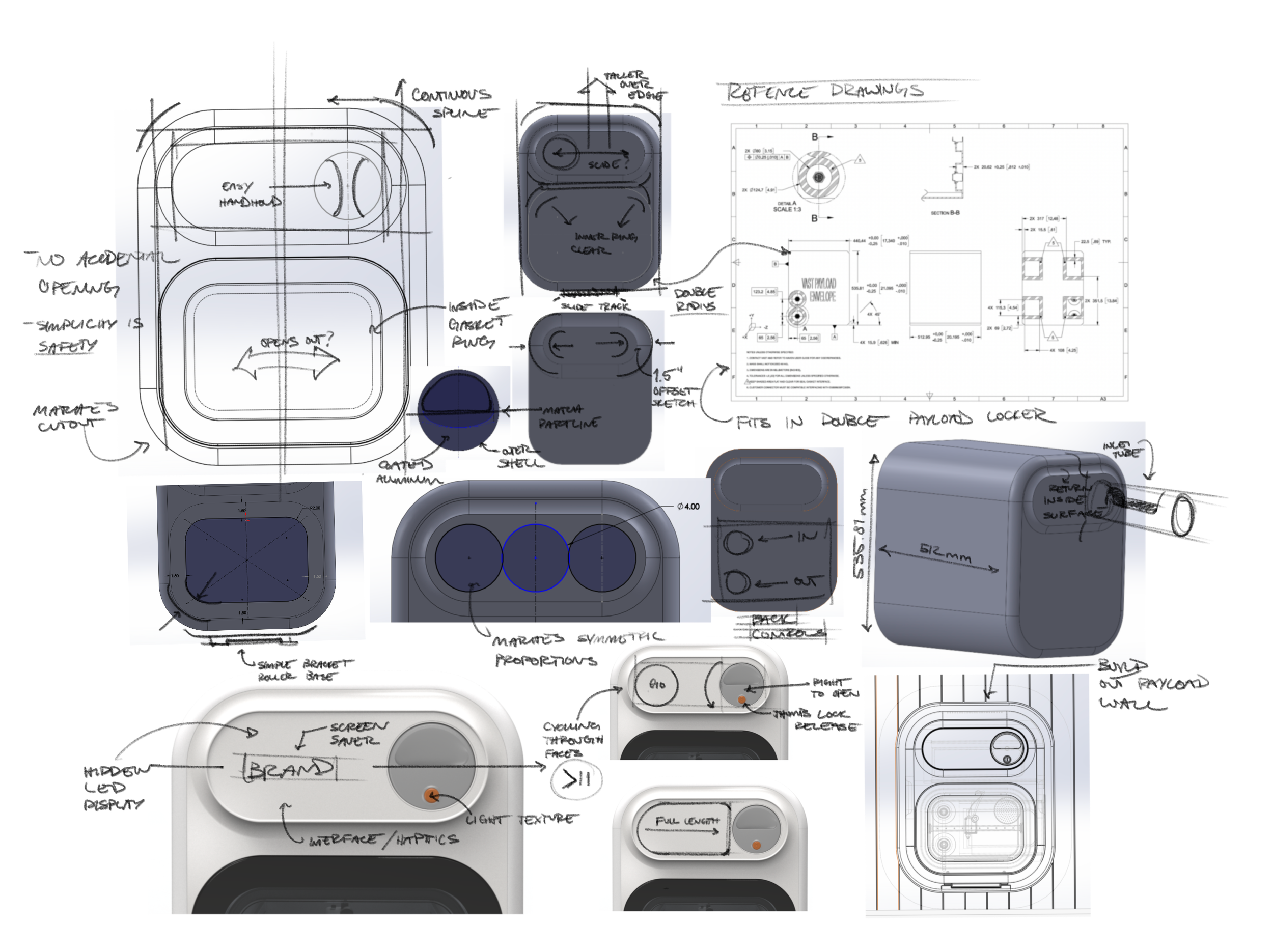

IDEATION

Concepts developed around user experience and habitat integration

During the ideation phase, I had to begin by building out the internal process of a standard refabricator, taking into account the essential features and dimensions. The exterior was then shaped to form comfortable geometries that support a calming environment.

FORM DEVELOPMENT

Solidworks translation to integrate payload constraints of Haven-2

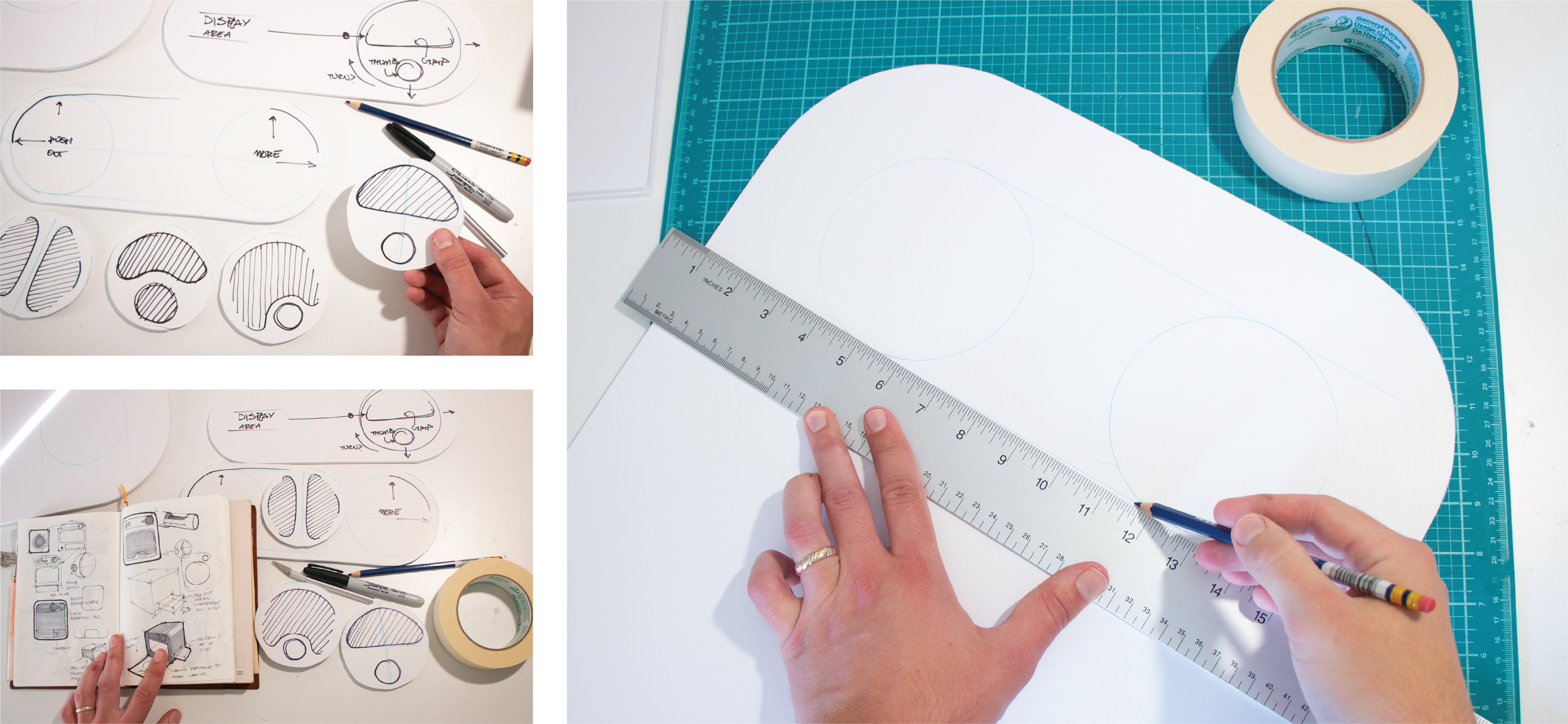

EXPLORATION

Rapid prototyping to develop scale and proportions

THIS IS FORGE

The ultimate recycler and fabrication system for life in deep space

Recycle, Re-print, Repeat

The Refabricator transforms waste material into usable feedstock for 3D printing through a fully integrated, closed-loop process.

INTERFACE

FORGE manages the complexity, crew confirms intent

All interactions with FORGE are designed to be simple confirmations to programming that has already been prepared via laptop or tablet. The appliance software takes care of the rest.

The deadfront LED display offers a seamless interface which is completely invisible when Forge is asleep. During use, it displays simple and reassuring information regarding the current task.

Concealed Mechanics

Supporting crew comfort by maintaining a calm, uncluttered habitat.

FORGE is mounted on a sliding track, which allows it to be pulled all the way out of the payload housing wall for easy-access, routine maintenance.